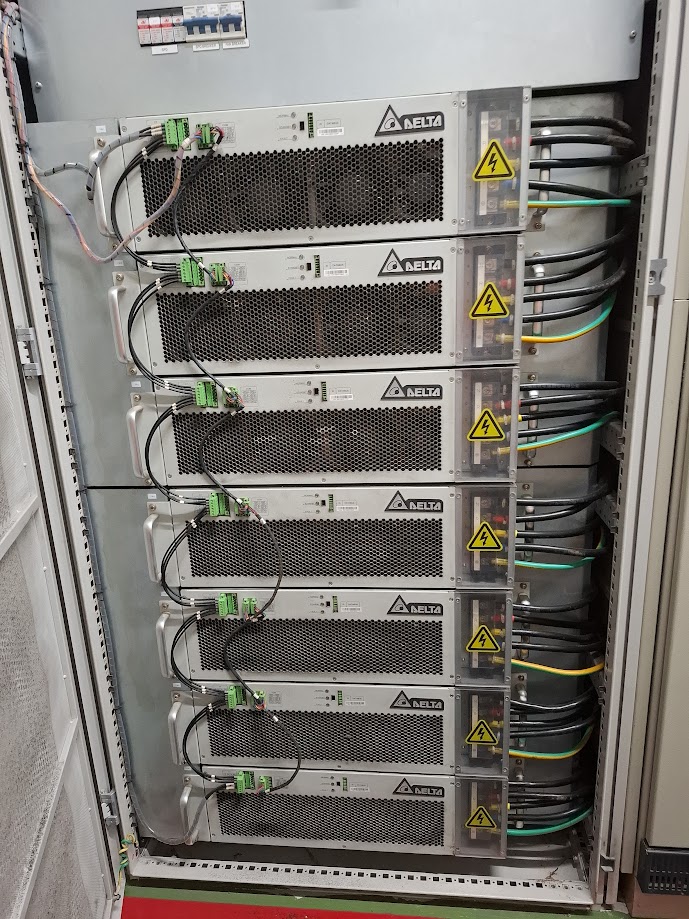

PM APF/SVG DELTA

Preventive Maintenance and equipment modification

Scope of work

| – Analyze the power quality by measuring Class A before installing and replacing all new equipment – Cleanliness and dust contamination / metal corrosion / rust of the cabinet – Check that all power and control cables are inspected for damage or connections – Check that all internal insulation is not broken or cracked – Check that all door ground wires are connected – Check that all bolts are properly tightened using an accurate torque wrench – Check the HMI panel (function and configuration) – Check that the cooling fan is working properly (cabinet / module) – Check that the DIP switch ID of each module is correct – Check the function of the circuit breaker – Check the error message and event log – Check the operation of all equipment – Analyze the power quality by measuring Class A after installing and replacing all new equipment |